EURO-TECH MOTOR CARE

Euro-Tech gear service and assembly plant is fully equipped with all gear service special tools, overhead crane of 3.2 ton, 10 ton and 120 ton press. We are able to service and repair to a centre distance of more than 2000 mm industrial gear units.

Service & Repair of Industrial Gear, Geared Motor, Fluid Coupling

Overhead

Cranes

20 Tons

10 Tons

100 Ton Press

6

Ton

Dynamic Balancing Machine

Training & Seminars

Benefits from Euro-Tech repair services:

GMEC training center provides: Both theory and hands-on training tailor to customers' needs.

Motor Assembly

Your one-stop solution for drive system assembly. GMEC provide expertise and critical equipment and facilities to assemble

Commissioning Service

- Trouble-free and smooth production from the very beginning.

- All possible mounting errors will be rectified before production starts, thus no unplanned shutdown.

- Proper start-up service reduces unnecessary discussion about warranty issues.

- Make troubleshooting easier in case of problem in the future due to availed reference vibration data.

Condition Monitoring Service

GMEC provide information on:

- Condition of motor components such as bearings, rotors, coil and etc

- Condition of both DE & NDE

- Necessity for re-alignments, rebuild of foundation and etc.

- Estimation of motor's life time expectant.

Troubleshooting Service

GMEC provide information such as

- Behaviour of electric motors during operation (vibration and temperature)

- Original condition of the motor compared to current condition

- All possible root causes for the problems

- Estimation of the motors expected life time

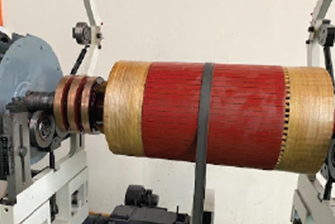

Dynamic Balancing Service (5.5 ton)

"State of the art" Schenck dynamic balancing machine 5.5 ton"

- Precision accuracy and maximum flexibility for universal application

- Range of huge components for dynamic balancing including:

- Rotors, Armatures, Fans, Pumps, Impellers and etc

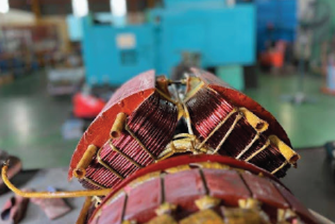

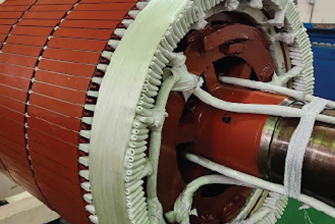

Overhaul & Rewinding Services

Some important processes:

- Insulation resistance test and drop voltage test to be carried out

- Thorough inspection to be carried out. Stator winding to be cut out properly

- Burn out motor insulation in electric oven before burnt stator coils stripped

- Steam cleaning the stator, rotor using chemical jet washer

- Bake dry stator, rotor and etc

- Mechanical measurement to be carried out

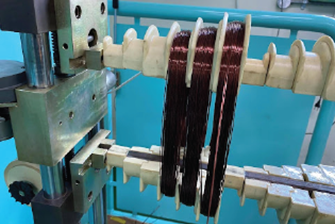

- High class copper wire and insulation material to be used for rewinding

- Insulation, surge comparison and other critical tests to be carried out

- High class varnish to be used to treat stator before oven baking proceeded

- Dynamic balancing to be carried if necessary before motor assembly

- No load test to be carried out and FAT to be conducted by client

- Service report with testing data to be provided upon motor delivery.